Bioplastic will soon replace conventional plastic…an emerging market

Agro based bioplastic and Biosensors

Bioplastic will soon replace conventional plastic…an emerging market

Agro based bioplastic and Biosensors

Plastic pollution is becoming a global concern. The mantra of "Reuse," "Reduce," and "Recycle" is also losing its impact because these measures are not sufficient to tackle the growing pollution caused by conventional plastics. Due to the high demand for plastic, its production has also increased significantly.

Statistics reveal that around 359 million tons of plastic were produced in 2018, while its consumption during the same year reached 385 million tons. This means that consumption exceeded production. This indicates that consumption surpassed production. There is immense demand for plastic, ranging from everyday items to industrial uses. It is extensively required in fields such as medical, agriculture, pharmaceuticals, textile industry, and packaging-related industries, among others. Plastic is being used on a massive scale. However, only a small portion of the plastic in use is recycled, while the rest dissolves into the environment in various forms, contributing to pollution.

Unfortunately, proper waste management is not being implemented effectively. Another issue is that when large plastic pieces are exposed to sunlight, they break down into microplastics or even nanoplastics due to the ultraviolet rays from the sun and the activity of microorganisms in the soil. These tiny particles significantly impact the surrounding ecosystems and biodiversity. This is why the concentration of plastic microparticles in the environment is steadily increasing. These microplastics dissolve into the soil and oceans, posing a threat to aquatic and terrestrial life. Plastics contain various chemical components, and when they break down into micro or nanoplastics, these particles retain the chemicals. Micro/nanoplastics are smaller than 5 mm in size.

Studies suggest that the increasing concentration of microplastics in the soil can be highly detrimental to agricultural systems. In aquatic environments, about 3% of microplastics end up in the oceans. Microplastic particles have been found in various aquatic species, including plankton, mussels, fish, sea reptiles, and birds.

To address this serious issue, scientists are accelerating research and studies related to biodegradable plastics. The goal is to swiftly reduce the use of conventional plastics. Biodegradable plastics are made from natural elements. Being made from biological materials, biodegradable plastics are environmentally safe and decompose easily into the soil when discarded. Their demand is increasing in industries related to agriculture and food packaging.

Dr. Sandeep Kumar Sharma, a senior scientist at CSIR-Indian Institute of Toxicology Research, Lucknow, one of the premier institutes of CSIR, and his team are not only advancing their study and research on biodegradable plastic but have also succeeded in taking this research a step further. Dr. Sharma and his team members stated that this research is not limited to the production of bioplastics; special attention has been given to its potential applications in other fields. Among these, the packaging of medical products, fruits, and beverages is a top priority.

Many instruments are used for testing in the medical field, and many of these tests are closely related to the daily lives of common people. These mainly include point-of-care devices, also known as 'point-of-care' devices, such as blood glucose testing, pregnancy tests, infection testing, and more. In addition, countless other areas, like detecting the quality of fruits and beverages during packaging, are also involved. Traditional plastic is used in all these areas, but the effort is to replace it with plastic made from bio-materials. This way, we can significantly reduce plastic pollution and help protect the environment.

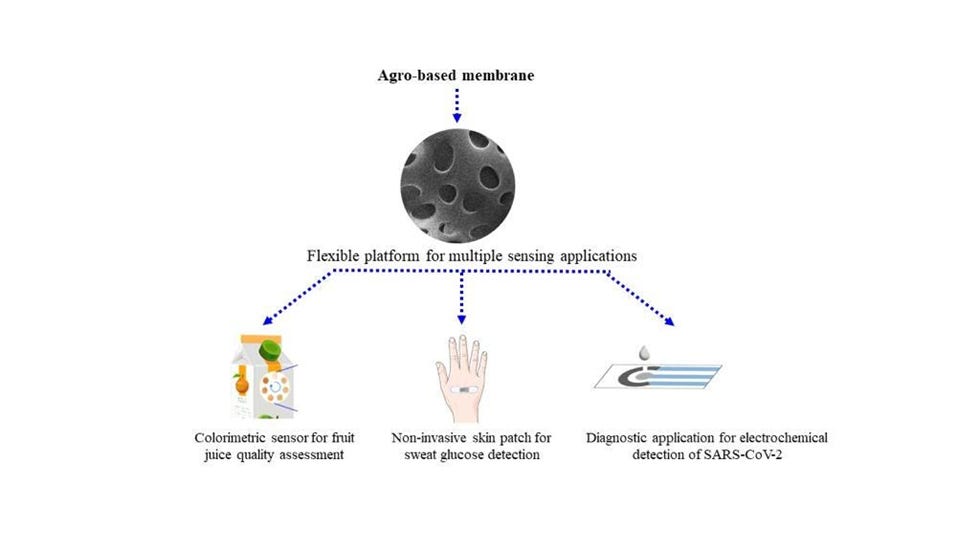

During their research, Dr. Sandeep Sharma and his team prepared a membrane by cross-linking polythenic acid obtained from corn, tapioca powder (easily available in the market), and powder developed from banana peel.. After development, several tests were conducted on the membrane to assess how it can replace traditional plastic. Another important finding from the study is that it can also be used in the field of electrochemical detection.

The study focused on three key aspects: gene-level identification of infections caused by deadly viruses such as SARS-CoV-2, detection of glucose levels in the body, and testing the quality of packaged fruit juices. With the success of these research initiatives, it is anticipated that in the future, this naturally safe plastic could replace the plastic-based tests and equipment currently used in the medical field. The membrane was evaluated for its quality, strength, and flexibility based on these parameters. Dr. Sharma stated that the demand for electrochemical detection is growing rapidly in the medical field due to its quick and accurate results. Consequently, the membrane was also tested to determine its conductivity.

Conductive substances can be used as sensors or electrodes for various tests under electrochemical detection. Research has demonstrated that this membrane is conductive. Following this discovery, the membrane was used to detect SARS-CoV-2 at the gene level. With this achievement, the biomaterial-based membrane holds potential for future use in testing for SARS-CoV-2.

The second significant test involves measuring glucose levels in the body. Wearable sensors are commonly used for various medical tests. These sensors, when in contact with the body, monitor and analyze its activities. The biomaterial-based membrane has been designed as a patch. During the research, glucose levels were tested by applying the patch to the skin. When the patch comes into contact with sweat, it effectively measures glucose. Currently, many patches available in the market are made of plastic. However, from a toxicity perspective, they are not entirely safe.

Dr. Sharma explains that the shelf life of fruits and various non-alcoholic beverages, including fruit juices, depends on several internal and external factors. Juices and other beverages undergo several processes during their production and packaging. Throughout this process, special attention is given to their color, taste, quality, and nutritional properties. It is also crucial to ensure that they do not spoil during these stages. If the juice begins to spoil, a furan compound, such as hydroxymethylfurfural (HMF), starts to form. This organic compound serves as an indicator, revealing whether the juice is fresh or has deteriorated. This can be easily detected using membranes made from agricultural materials. Some chemical testing methods applied to the membrane are available at the institute, for which they have also received a patent. This test allows the determination, through the membrane, whether the fruit juice is fresh or spoiled. The quality of the juice can be assessed based on the presence or absence of furan compounds.

This membrane was designed to identify hydroxymethylfurfural. It was used as a colorimetric sensor, where the quality of the juice is determined by the color change triggered by the indicator. The toxicity of the biomaterial was also tested as part of the research. For this, the biomaterial was provided as food to key organisms in the food chain, such as earthworms, zebrafish, and algae. The results showed that it is completely safe.

Conductive – An object or substance that has the ability to allow heat or electricity to flow through it.

Electrochemical detection – A process where biological samples are analyzed using biosensors. In this method, electronic signals are applied to biological objects to detect specific responses.

by:

P.Datt.Saxena

Credit:

Carbohydrate Polymers

Contents lists available at ScienceDirect

Carbohydrate Polymers.

journal homepage: www.elsevior.com/locate/carbpol

Polylactic acid/tapioca starch/banana peel-based material for colorimetric and electrochemical biosensing applications

Pawankumar Rai", Srishti Mehrotra, Krishna Gautam, Aditya K. Kar, Apoorva Saxena, Satyakam Patnaik, Sadasivam Anbumani, Ashok Pandey, Smriti Priya", Sandeep K. Sharma

Food drug and Chemical Toxicology Group CSIR-Indian Institute of Toxicology Research, India Regulatory Toxicology Group, CSIR-Indian Institute of Toxicology Research, India Centre for Innovation and Translational Research, CSIR-Indian Institute of Toxicology Research, India System Toxicology & Health Risk Assessment Group, CSIR Indian Institute of Toxicology Research, Vishvigyan Bhawan, 31, Mahatma Gandhi Marg Lucknow 226001 Uttar Pradesh, India

Academy of Scientific and Industrial Research (ACSIR), Ghaziabad 201002.